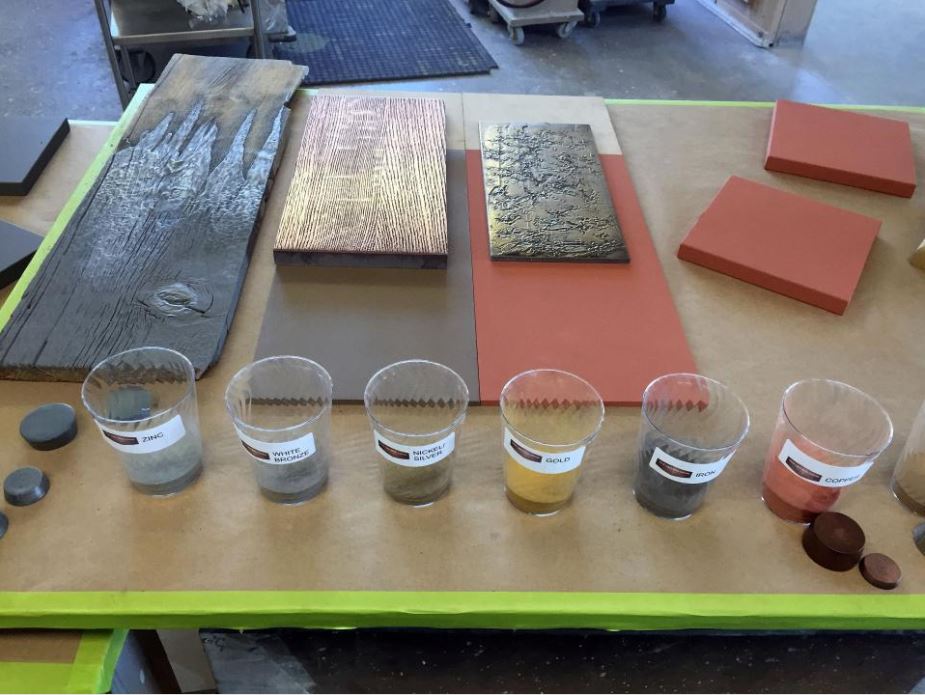

Great Lakes Metal Coating is a division of Hylan Design that offers a unique liquid metal veneer. We offer an array of patterns, textures, and patinas under and over the metal, and will work with the imaginations of our partners and customers to create extraordinary pieces and applications.

[/highlight][/span7] [row] [row]Examples

[row] [/row]

What It Is

Our metal veneer is an exclusive form of re-cycled pulverized real metals combined in a spray-able liquid binder. Since it is cold-sprayed, the weight of the metal is significantly reduced and can be applied to almost any rigid surface. It is extremely durable, waterproof and resistant to heat and most household chemicals. It is also suitable for both indoor and outdoor projects.

The liquid metal veneer is made of 100 percent recycled metal. Less spray metal is needed to achieve the same desired look of traditional metal. This means there is a greater cost savings to our clients. Once applied, it has excellent adhesion properties and can be used on most surfaces including MDF, plaster, plasterboard, glass, concrete, fiberglass, plastic, and even paper mache.

Great Lakes Metal Coating offers an array of patterns, textures, and patinas under and over the metal. We are excited to share the imaginations of our partners and customers to create extraordinary pieces and applications.

Visit www.GreatLakesMetalCoating.com to learn more or

Contact us today to set up a tour!

[/highlight][/span7] [span4]

[/span4][/row]

[/span4][/row]

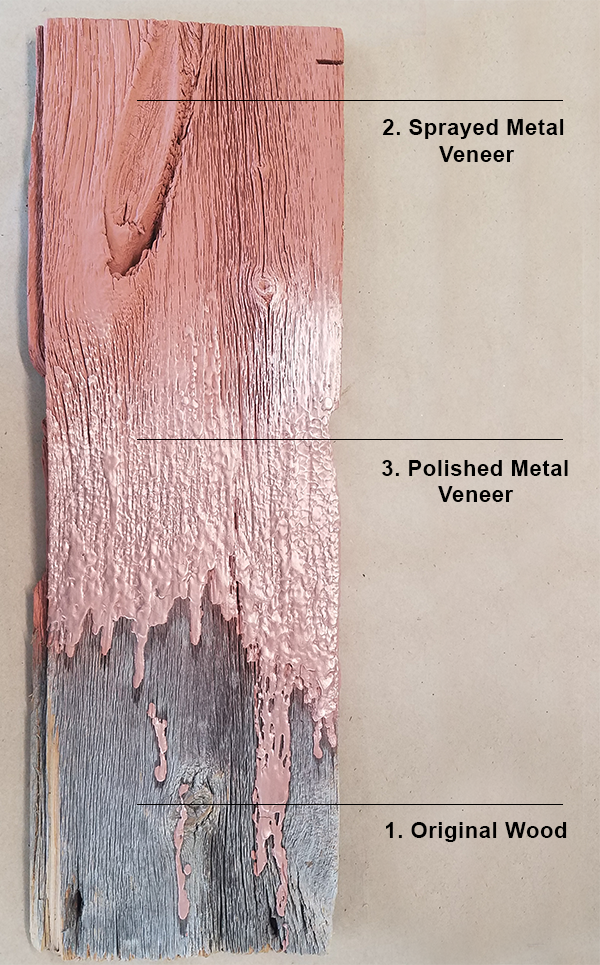

How It Works

Coverage Guide: Approximately one meter square per one kilogram of metal veneer liquid is applied depending on the absorbency and texture of the base material. The more textured the finish, the more liquid material is required. After application, the liquid metal coating will take between one to three hours to dry depending on humidity and room temperature.

Finishing: When liquid metal veneer dries, it will have a matte finish due to oxidization that occurs after contact with the air. Lightly sanding the surface will produce a pure metal finish. Further efforts of sanding and/or polishing will produce ever increasing grades of shine and luster that provide exciting metal finish possibilities. Other creative processes can be applied such as acid wash, patina wash, sandblast, wire brush and machined textures. Customers are encouraged to experiment with the liquid metal coating for all sorts of creative metal applications.

Sealing: As with any real metal, it must to be sealed to prevent tarnishing (unless a finish that continues to patinate over time is desired). Metals may be sealed with Nano-Coating, hard wax oil, or a clear coat urethane.

[/highlight]

Hylan has trained a team of highly skilled artisans specializing in the application of real metal finishes to virtually any substrate; custom coatings and finishes available. Please contact or visit us to begin imagining your ideas into finished metal design.

[row] [span6][/span6] [span6]

[/span6] [/row]

Visit www.GreatLakesMetalCoating.com to see more